The Russian Lathe Accident: A Stark Reminder Of Industrial Dangers

The industrial world, while a cornerstone of modern civilization, harbors inherent risks that can, at times, manifest in catastrophic ways. The phrase "Russian Lathe Accident" immediately conjures images of one such tragedy, a chilling reminder of the raw power of machinery and the devastating consequences when safety protocols falter. This article delves into the specifics of a particularly harrowing incident that gained widespread attention, exploring its implications for industrial safety worldwide and underscoring the critical importance of vigilance in manufacturing environments.

The incident involving a lathe machine in Russia serves as a somber case study, highlighting not just the immediate danger posed by powerful industrial equipment, but also the broader issues surrounding workplace safety, training, and accountability. Understanding these events is crucial for preventing future tragedies and fostering a culture where human life is always prioritized over production quotas or convenience.

Table of Contents

- A History of Industrial Accidents in Russia

- Understanding the Lathe Machine: A Powerful Tool

- The 2020 Russian Lathe Accident: What We Know

- The Anatomy of a Tragedy: Contributing Factors

- The Human Cost and Psychological Trauma

- Global Implications for Industrial Safety

- Preventing Future Tragedies: Best Practices in Manufacturing

- Russia's Industrial Landscape and Safety Culture

A History of Industrial Accidents in Russia

Industrial accidents are not a new phenomenon, and Russia, with its vast industrial base spanning from Eastern Europe to North Asia, has unfortunately seen its share of such incidents. The country, the world's largest by area and extending across eleven time zones, has a long history of heavy industry. This scale of operation naturally brings with it increased risks. For instance, in 1993, the world witnessed a catastrophic accident at a factory in Russia that sent shockwaves through the manufacturing industry. The explosion at a Russian lathe, a machine used for shaping metal, turned what should have been a routine day of production into a nightmare scenario. This earlier incident, though perhaps less widely documented in the digital age, serves as a stark precursor to more recent events, underscoring a persistent challenge in maintaining stringent safety standards. Furthermore, anecdotal evidence from experienced workers paints a grim picture of safety shortcuts. One greybeard coworker, with over 40 years of experience, recounted a terrifying incident from the late 90s where a colleague was tragically pulled into an Integrex machine. The chilling detail? All safety interlocks had been removed in that shop, a decision made by management for "ease of set up," despite repeated warnings about the safety concerns. These stories highlight a recurring theme: the dangerous trade-off between efficiency and safety, a choice that often leads to irreversible consequences. Such historical patterns emphasize that the "Russian Lathe Accident" is not an isolated event but part of a larger, systemic issue that demands continuous attention and reform.Understanding the Lathe Machine: A Powerful Tool

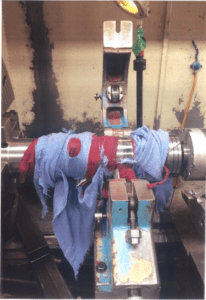

To fully grasp the severity of a Russian lathe accident, it's essential to understand what a lathe machine is and why it poses such significant risks. A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. These machines are fundamental to manufacturing, used in everything from automotive parts production to woodworking and metal fabrication. They are indispensable for shaping metal, plastic, and wood with high precision. However, the very power and precision that make lathes so valuable also make them incredibly dangerous. They operate at high speeds, generating immense rotational force. Loose clothing, long hair, jewelry, or even a momentary lapse in concentration can lead to entanglement. The rotating parts can quickly draw in anything that comes into contact, with devastating force. Chips of metal can fly off at high velocity, posing projectile hazards. Without proper guarding, emergency stop mechanisms, and strict adherence to operational protocols, a lathe can transform from a precision instrument into a deadly hazard in an instant. This inherent danger is precisely why the "Russian Lathe Accident" serves as such a potent warning.The 2020 Russian Lathe Accident: What We Know

The most widely recognized "Russian Lathe Accident" in recent memory is the tragic event that occurred in November 2020. This incident gained significant, albeit grim, notoriety due to a shocking video that circulated widely online, particularly on platforms like Reddit. The footage, though disturbing, served as an undeniable testament to the suddenness and severity of industrial accidents, unequivocally highlighting the urgent need for stringent safety protocols in such environments.The Viral Video and Its Impact

In 2020, a shocking video was uploaded on Reddit showing a fatal industrial accident involving a lathe machine in Russia. The video depicts a man walking across a machine shop where a large lathe is running. The footage then shows an inexperienced individual getting dangerously close to the operational lathe machine. The precise sequence of events leading to the fatal outcome is not entirely clear from the brief clip, but the immediate and devastating consequences are horrifyingly evident. The video, often referred to as the "Russian pink mist lathe accident video" due to the horrific nature of the incident, quickly went viral. Although the original user deleted their account, the video resurfaced and went viral again, with one post receiving nearly 16k upvotes and over 1900 comments, underscoring the profound impact and shock it had on viewers worldwide. This widespread dissemination, despite its graphic nature, arguably served to raise awareness about the extreme dangers present in industrial settings.Location and Lack of Detailed Reports

The Russian lathe accident happened in November 2020 at a Kamaz factory in the Republic of Tatarstan, Russia. Kamaz is a well-known Russian manufacturer of trucks, buses, and engines, indicating a large-scale industrial operation. Despite the viral nature of the video and the clear fatality, there aren't any detailed official reports widely available on what exactly happened. This lack of comprehensive information is concerning, as detailed investigations are crucial for understanding the root causes of such accidents and implementing effective preventative measures. The absence of public reports makes it harder to learn specific lessons from this particular "Russian Lathe Accident," forcing reliance on the visual evidence and general industrial safety principles.The Anatomy of a Tragedy: Contributing Factors

The tragic "Russian Lathe Accident" of 2020, much like other industrial fatalities, is rarely the result of a single error. Instead, it's typically a confluence of factors, often stemming from systemic failures, human error, and a disregard for established safety standards. Understanding these contributing elements is vital for preventing similar incidents in the future.The Peril of Removed Safety Interlocks

One of the most critical safety features on modern industrial machinery, including lathes, are safety interlocks. These mechanisms are designed to prevent the machine from operating if a guard is open, a door is unsecured, or if an operator is in a hazardous zone. They are a last line of defense, ensuring that human interaction with dangerous moving parts is minimized. However, as anecdotal evidence suggests, it's not uncommon for these vital safety features to be bypassed or outright removed in some industrial settings. The reason often cited is "ease of set up" or to speed up production. This dangerous practice, driven by a misguided pursuit of efficiency, directly compromises worker safety. When a greybeard coworker described a late 90's Integrex accident where all machine door interlocks were removed, despite warnings to the boss, it illustrates a pervasive problem. Such deliberate disabling of safety features turns inherently dangerous machines into deathtraps, making a "Russian Lathe Accident" not just possible, but tragically probable.The Role of Inexperience and Negligence

The viral video of the 2020 Russian lathe accident clearly depicts an "inexperienced individual" getting near the running machine. Inexperience, coupled with a lack of proper training, is a significant contributing factor to industrial accidents. New workers might not fully appreciate the immense power and speed of a lathe, or they might not be aware of the specific hazards associated with certain operations. Beyond inexperience, negligence – whether on the part of the operator or the management – plays a critical role. An operator might neglect to follow Lockout/Tagout procedures, wear appropriate Personal Protective Equipment (PPE), or maintain a safe distance from moving parts. Management, on the other hand, might be negligent in providing adequate training, enforcing safety rules, conducting regular machine maintenance, or, as seen with the interlock removal, actively compromising safety for production gains. The combination of an inexperienced individual operating or approaching a machine with compromised safety features creates a highly volatile situation, setting the stage for a catastrophic "Russian Lathe Accident."The Human Cost and Psychological Trauma

Beyond the immediate, devastating physical consequences of a "Russian Lathe Accident," there lies a profound and lasting human cost. For the victim, the accident is fatal, ending a life in a sudden and horrific manner. The impact, however, extends far beyond the individual directly involved. Families are left to grapple with unimaginable grief, the sudden loss of a loved one, and often, the loss of a primary income earner. The emotional and financial void left by such a tragedy can be immense and long-lasting. Witnesses to such an event also bear a heavy burden. Seeing a colleague or even a stranger suffer such a violent end can lead to severe psychological trauma, including Post-Traumatic Stress Disorder (PTSD), anxiety, depression, and survivor's guilt. The memory of the "Russian pink mist lathe accident video" is deeply disturbing for viewers, but for those who were physically present, the experience is far more visceral and scarring. The entire workplace can be affected, leading to a decline in morale, increased fear, and a pervasive sense of vulnerability. This psychological toll underscores that industrial accidents are not merely statistics; they are human tragedies with far-reaching ripple effects that impact individuals, families, and communities for years to come.Global Implications for Industrial Safety

The "Russian Lathe Accident" of 2020, and similar incidents, serve as a stark global reminder that industrial safety is a universal concern, transcending national borders and economic systems. While the specific incident occurred in Russia, the lessons learned are applicable to manufacturing facilities everywhere, from the bustling factories of Asia to the highly automated plants of Europe and North America. The viral nature of the video ensured that this particular tragedy resonated internationally, sparking discussions about workplace hazards and the ethical responsibilities of employers. This incident underscores several critical global implications: * **Universal Vulnerability:** Regardless of a country's level of development or regulatory framework, the fundamental dangers of powerful machinery remain. Human error, mechanical failure, and a lapse in safety culture can lead to catastrophic outcomes anywhere. * **The Power of Visual Evidence:** The "Russian lathe machine incident footage real video" became a powerful, albeit horrifying, educational tool. It bypassed language barriers and official reports, delivering an undeniable message about the severity and suddenness of industrial accidents. This highlights how digital media can force uncomfortable but necessary conversations about safety on a global scale. * **Reinforcement of Best Practices:** The accident serves as a renewed call for adherence to international best practices in machine guarding, operator training, risk assessment, and safety management systems. It reinforces the notion that shortcuts in safety are never acceptable, regardless of perceived benefits in speed or cost. * **Accountability and Transparency:** The lack of detailed official reports on the 2020 Russian lathe accident is a concerning aspect. In a globalized world, transparency in accident investigations is crucial for sharing lessons learned and holding responsible parties accountable. This incident implicitly calls for greater international cooperation in promoting workplace safety standards and ensuring thorough investigations are conducted and shared. Ultimately, the "Russian Lathe Accident" is not just a Russian problem; it's a human problem. It's a reminder that industrial progress must always be balanced with an unwavering commitment to protecting the lives and well-being of workers worldwide.Preventing Future Tragedies: Best Practices in Manufacturing

The tragic "Russian Lathe Accident" provides invaluable, albeit painful, lessons for the manufacturing industry globally. Preventing future tragedies requires a multi-faceted approach, emphasizing proactive measures, continuous training, and a robust safety culture. Adhering to the principles of E-E-A-T (Expertise, Authoritativeness, Trustworthiness) in safety management is paramount, ensuring that policies are based on expert knowledge, backed by authoritative standards, and implemented with unwavering trustworthiness. Here are key best practices that can significantly reduce the risk of industrial accidents: * **Comprehensive Risk Assessment:** * Regularly identify potential hazards associated with all machinery, especially high-risk equipment like lathes. * Evaluate the likelihood and severity of potential accidents. * Develop and implement control measures to eliminate or mitigate identified risks. * **Robust Machine Guarding and Safety Interlocks:** * Ensure all machines are equipped with appropriate guards that prevent access to dangerous moving parts. * Verify that safety interlocks are fully functional and never bypassed or removed. This is a non-negotiable principle; the history of accidents, including those related to the "Russian Lathe Accident" where interlocks were removed, clearly demonstrates their critical importance. * Regularly inspect and maintain all safety devices. * **Thorough Operator Training and Certification:** * Provide comprehensive training for all machine operators, covering safe operation procedures, emergency protocols, and hazard recognition. * Ensure that only trained and certified personnel operate complex machinery. The incident involving an "inexperienced individual" near the lathe underscores this necessity. * Implement ongoing refresher training to reinforce safety knowledge and adapt to new technologies or procedures. * **Strict Adherence to Lockout/Tagout (LOTO) Procedures:** * Mandate LOTO procedures for all maintenance, repair, or cleaning activities on machinery. This ensures that machines are de-energized and cannot be accidentally started. * Provide proper equipment and training for LOTO, and rigorously enforce its application. * **Appropriate Personal Protective Equipment (PPE):** * Enforce the mandatory use of appropriate PPE, including safety glasses, hearing protection, gloves (where safe and non-entangling), and protective footwear. * Ensure clothing is not loose and hair is tied back to prevent entanglement in rotating machinery. * **Clear Safety Signage and Communication:** * Install clear, visible safety signs and warnings around machinery. * Foster an open communication culture where workers feel empowered to report hazards or near misses without fear of reprisal. * **Regular Safety Audits and Inspections:** * Conduct periodic internal and external safety audits to identify non-compliance and areas for improvement. * Implement a system for corrective actions and track their completion. * **Promoting a Strong Safety Culture:** * Leadership must demonstrate a visible commitment to safety, prioritizing it over production targets. * Encourage employee involvement in safety committees and initiatives. * Recognize and reward safe behaviors, while addressing unsafe practices promptly and effectively. By embedding these practices into the core of manufacturing operations, companies can create environments where the likelihood of a "Russian Lathe Accident" or any similar industrial tragedy is drastically reduced, ensuring the well-being of their most valuable asset: their workforce.Russia's Industrial Landscape and Safety Culture

Russia, or the Russian Federation, is a country spanning Eastern Europe and North Asia. It is the largest country in the world, and extends across eleven time zones, sharing land borders with fourteen countries. Its vast geography, bordering the Arctic Ocean to the north and the Pacific to the east, with a short coastline on the Baltic Sea, reflects its immense natural resources and a long-standing emphasis on heavy industry. From mining and metallurgy to machinery and defense, Russia's industrial sector is diverse and significant on a global scale. This extensive industrial activity naturally brings with it the inherent challenges of maintaining robust safety standards across numerous enterprises. The "Russian Lathe Accident" at a Kamaz factory in Tatarstan is a localized incident within this vast industrial landscape, yet it raises questions about the broader safety culture. While Russia has established labor laws and safety regulations, their enforcement and adherence can vary. The historical context, including the 1993 factory explosion and anecdotal accounts of safety interlocks being removed, suggests that a pragmatic, sometimes lax, approach to safety might persist in certain segments of the industry. Education in Russian is still a popular choice for both Russian as a second language (RSL) and native speakers in Russia, and in many former Soviet republics, and Russian is still seen as an important language for children to learn in most of the former Soviet republics. This educational foundation could be leveraged to instill a stronger safety consciousness from an early age, emphasizing the importance of rigorous adherence to protocols in technical and vocational training. Ultimately, while incidents like the "Russian Lathe Accident" are tragedies, they also serve as critical catalysts for introspection and reform within Russia's industrial sector, pushing for a more consistent and uncompromising commitment to worker safety.Conclusion

The "Russian Lathe Accident" of 2020 stands as a grim testament to the enduring dangers within industrial environments when safety is compromised. The viral footage, though harrowing, served as an undeniable, global warning, illustrating with brutal clarity the instantaneous and catastrophic consequences of powerful machinery combined with human error, inexperience, or negligence. While the specifics of the incident at the Kamaz factory in Tatarstan remain somewhat shrouded due to a lack of detailed official reports, the core lessons are abundantly clear: safety interlocks are non-negotiable, comprehensive training is paramount, and a proactive safety culture must permeate every level of an organization. This tragic event, alongside historical incidents of similar nature, underscores the universal truth that human life must always take precedence over production targets or convenience. It is a powerful reminder for manufacturers, safety officers, and workers worldwide to constantly re-evaluate and reinforce their safety protocols. Let this "Russian Lathe Accident" not be just another statistic, but a catalyst for change, driving industries towards a future where such preventable tragedies are truly a thing of the past. We encourage you to reflect on the safety practices in your own workplace or industry. Share your thoughts and experiences in the comments below, or explore our other articles on industrial safety and best practices to contribute to a safer working world for everyone.- Don Luna Photos

- Palatka Flooring Palatka Fl

- Nonzero Newsletter

- Pressley Hossbach

- Onlyfans Lowkeydeadinside

Russian mine accident leaves 36 dead - BBC News

Engineering firm fined after worker suffered multiple injuries - SHP

Smoke Rises After Explosion at Russian Warehouse - The New York Times